Construction of a 5" Merchant Navy '35006'

Part 4 of an Article by Kevin Neate

Constructing the Ashpan and Grate

In full size the ashpan is a complex steel fabrication with inner and outer sections that fit over the locomotive frames.

There are dampers front and rear operated from the cab, and a single lever to open the ash hoppers.

To replicate this in 5" is not easy, and I found the KW drawings of no use at all apart from basic dimensions.

Most of what I made here was from measuring off my loco, looking at photos, looking at the restored 35006 and adding a bit of common sense.

Full size 35006 had a new ashpan made during restoration.

I have pictures of the ashpan for 35028 and of course the two are different.

Whatever is made here will be very visible on the finished loco, and as always on this build is very slow and fiddly and it took me a long time to sort out.

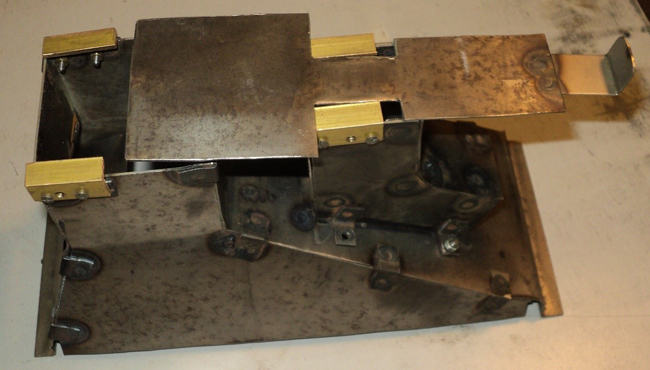

The ashpan was made in two stages, firstly the hoppers.

I knew a lot of detail about the dampers was missing and did the second stage with the dampers and ash drops after a close look at 35006, and finding a picture of the 35006 ashpan upside down, before being fitting to the loco.

Using 0.8mm mild steel sheet, I made an inner hopper and a pair of outer hoppers, with solid connecting bars that support the grate.

The inner hopper was spot welded using tabs, the outer one Mig welds and silver solder.

First the inner hopper that is basically a tapering box with ash outlets front and rear of the bissel truck axle.

I cut out the approximate shapes from card to work out the main inner hopper.

There are front and rear sloping plates, and two side plates also sloping with various bends.

Once OK with this and after checking that the bissel truck will not foul the ash outlets at full swing, I cut sheet steel to size and spot welded it all together using tabs.

I used the spot weld method as it is very quick and doesn't distort the sheet metal too much.

The inner hopper cannot be seen, so the unsightly tabs are not a problem.

The spot welder came from a junk sale, for a very well spent £20.

Then there is a secondary hopper attached to the main hopper with screws.

This was made the same way.

Both hoppers protrude below the bissel truck by about 3/16”.

Full size uses a single lever and lots of linkages that empty all four ash hoppers in one go.

I very much doubt this is possible in 5" gauge, so for the inside hopper I squared off the ends of both ash outlets on a linisher, and then fitted a plate that covers both outlets.

The plate is held by angles, and when pulled back from underneath drops off releasing the ash.

If the ashpan is made as a solid "box" no air will get in, so there is a need to fit opening dampers as per full size.

The ashpan on my King needed many air holes adding to get the fire burning well.

The Bagnall with its marine boiler guzzles air and the air howls in like a banshee when the loco is working hard.

The MN will need plenty of air letting into the firebox so I fitted dampers front and rear on the three ashpans.

The rear centre damper can only be operated from the cab.

The front inner damper is opened along with the front dampers on the outer ash pans using a cross rod and a lever on the righthand side.

The rear dampers on the outer ashpans are operated with levers and the distinctive triangular connector.

This arrangement follows full size.

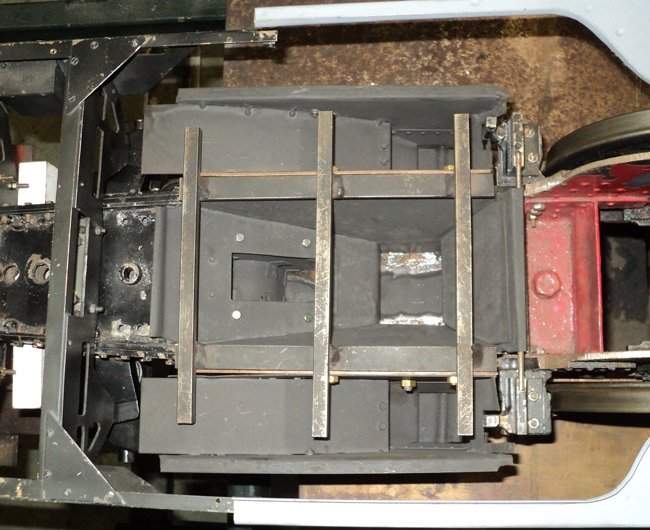

The two outer ashpans top sections are next.

The KW drawings were again of no use, so again what I made was taken off photos and measuring of my loco.

I cut templates as before and from these made two upper hoppers, this time using hidden MIG welds.

The inner hopper has a front tab that sits on the boiler support at the front and at the rear sits on the drag box.

It is held in place by the outer hoppers.

The outer hoppers were made the same way but were a nightmare to set up, and I eventually had to cut bits off and fitted spacers with a hole for M5 screws into the second pair of large holes in the double rear frames; these keep the hoppers correctly aligned to miss the bissel truck.

The boiler was on and off countless times doing this !

Once aligned I spotted through the spacers and drilled holes in the hoppers to secure with M5 screws.

Once the boiler is in place the ashpan assembly presses against but is not screwed to the foundation ring.

I then screwed angles to the outer ashpans and welded 3 cross bars to support the grate.

After a lot of deliberation and trial and error I made a grate in four sections from 5 x 10 mm steel with 6mm spacers welded between.

These can be dropped in and pulled out through the fire hole using hooks and magnets and can be tipped to drop ash out.

A bar can be pushed up from the inner hopper to break the grate if necessary.

The small lower hopper with the ash drop is far more difficult to make and this was done using MIG welds, and the ribs and base plate silver soldered.

There are some odd angles and a lot of guesstimation to make something that looks realistic.

The lower hopper must also not foul on the bissel truck at full swing.

This fits to the upper hopper using 12 BA screws.

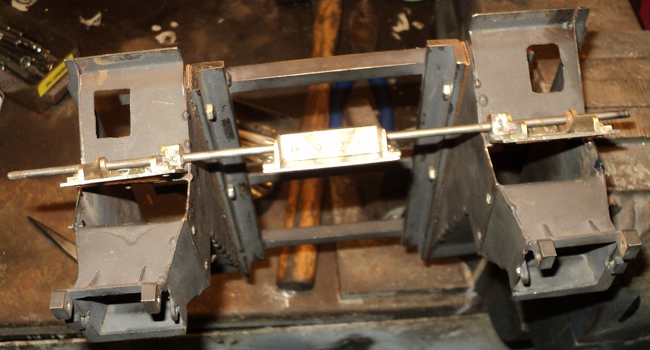

Now we come to the dampers.

The rear dampers on the outer ashpans are pretty straightforward, made off photos and with hinges, levers etc. and the triangular connectors.

The centre rear damper is hinged with a lever into the cab.

The front dampers are all worked together with a lever on the RHS that connects to a cross rod that connects all three damper doors.

I had to elongate the relevant hole in the frame to get the cross rod through.

The front centre damper hangs on the cross rod and has no hinges, and this is a bit of a cheat but works OK.

I fitted a baffle in the inner hopper to direct ash away from the front damper.

It is easy to make the parts, the dampers are assembled to the cross rod using M3 allen screws, it is tricky to get it all together but appears to work as it should.

The last stage is the ash empty for the two outer hoppers.

This uses another cross bar – that somehow just misses the underside of the bissel truck - to connect the two and is operated by a lever on the LHS to turn plates at the bottom of each hopper.

The lever has a tube and clamp.

The drop plates pivot on the centre bearing, and are turned by a linkage all as per full size.

Then there are four levers and linkages into the cab base to operate the dampers, that can only be finished later on.

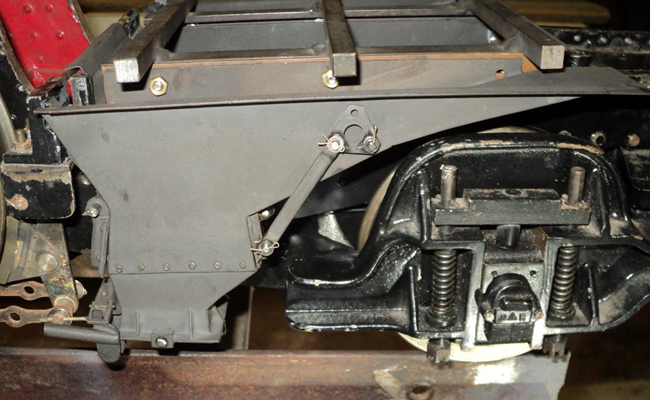

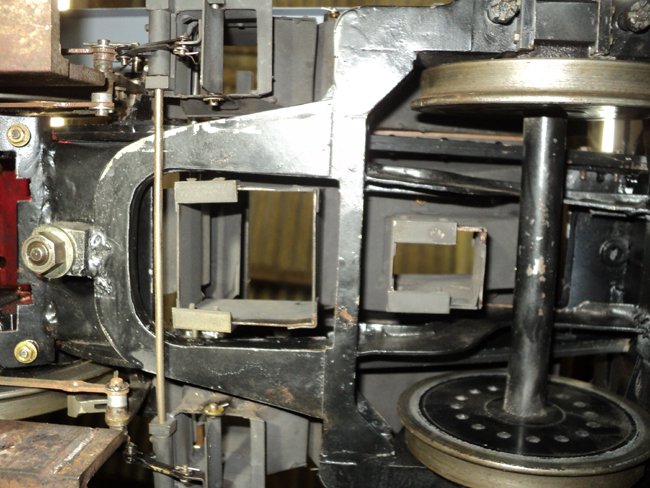

This side view shows the M5 bolts and nuts that secure the ashpan to the frames.

The front and rear damper can be seen in the closed position, and note the operating lever for the outside ashpan door.

The safety latch is lifted first, then a bar is inserted into the hollow tube and moved upwards, opening the bottom door, just like full size.

Once done I put the boiler back on and did a test with a few shovelfuls of wood burner ash through the firehole, and then opened the ash drops.

It all works incredibly well.

But the only way to find out if the dampers will work is to light a fire !

And finally, a view of the underside of the ashpan, as fitted to the loco, and showing the four ash drops.

It's all a bit of a squeeze, and not much clearance around the trailing truck.

The outside hopper control rod is fitted last, as it sits below the trailing truck.

Making the ashpan has been quite a challenge and very time consuming and I think mine now looks and works something like the one on 35006, with the necessary adaptations suitable for 5" gauge.

Along the way I have had to cut and grind off small areas on the frames and bissel truck.

I have added lots of photos here, as it is quite impossible to explain it all in text, never mind give dimensions.

No two 5" Merchant Navy models are going to be the same, so I think any drawings will have to be "check on job".